CNC Repair service in Delhi, Gurgaon, Noida, Faridabad, Ghaziabad, and Greater Noida

CNC machine is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The CNC process runs in contrast to – and thereby supersedes – the limitations of manual control, where live operators are needed to prompt and guide the commands of machining tools visa levers, buttons, and wheels. A CNC system might resemble are regular set of computer components, but the software programs and consoles employed in CNC machining distinguish it from all other forms of computation. If you are interested in utilizing CNC manufacturing to produce various products. When a fault or breakdown occurs with a CNC milling machine it’s compulsory to repair the problem quickly. Failing to do so may lead to the problem worsening or causing more damage, which is often harder and more costly to fix. There is a range of specialist CNC milling repair services out there, but we firmly believe that we offer a service that goes above and beyond that many engineers are capable off.

CNC Machine Repair and Maintenance services in Delhi, Gurgaon, Noida, Faridabad, Ghaziabad, and Greater Noida

When a CNC system is activated, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks are specified, much like a robot. In CNC programming, the code generator within the numerical system will often assume mechanisms are flawless, despite the possibility of errors. Whenever a CNC machine is directed to cut in more than one direction simultaneously. The placement of a tool in a numerical control system is outlined by a series of inputs known as the part program. With a numerical control machine , programs are inputted via punch cards . By contrast, the programs for CNC machines are fed to computers through small keyboards. CNC programming is retained in a computer’s memory the code itself is written and edited by programmers. CNC stands for Computer Numerical Control, it also plays an important role in the manufacturing industry. These complex machines are controlled by a computer and provide a level of efficiency, accuracy and consistency that would be impossible to achieve through a manual process.

CNC MACHINE PROGRAMMING

In CNC manufacturing, machines are operated via numerical control, wherein a software program is designated to control an object. The language behind CNC machining is alternately referred to as G – code , and its written to control the various behaviors of a corresponding machine , such as the speed, feed rate and coordination. Basically, CNC machine makes it possible to pre – program the speed and position of machine tool functions and run them via software in repetitive, predictable cycles, all with little involvements from human operators. There are also many types of CNC machines like – CNC Milling Machine, CNC Router, CNC Plasma Cutting Machine, CNC Lathe Machine, CNC Laser Cutting Machine, CNC Waterjet Cutting Machine, CNC Electrical Discharge Machine and last is CNC Grinder Machine and there are also advantages of this machine like - CNC Machining Produces Little to no waste, Zero Defects and Greater Accuracy, Faster and Efficient Production, Quicker Assembly, Enhanced Personal Safety, Reduction in Energy Consumption, CNC Machining Leads to Lower Production costs and the biggest disadvantages of running CNC machine is the rate at which parts are produced. An open loop system provides feedback to the control using an encoder. Before changing tools manually, wait for the machine axes to come to a complete stop. The CNC machine maintenance is also compulsory it should be get checked by the hydraulic pressure and fluids, making sure they are operating at the right levels. Check lubrication operating levels, and replenish if necessary make sure the cooling unit is operating correctly. Clean off the window, door, and lights of the machine so you can easily see inside. To get in this job we have first training like we are taught how to get well trained - Training, students learn skills including - Reading blueprints and using computer – aided design [CAD] and computer – aided manufacturing [CAM] software programs. Interpreting geometric dimensioning and tolerancing. Programming setup, operation and disassembly of CNC lathes and mills. There are three main types of errors – Geometric, cutting force and thermal errors are the three main sources of error which affects the accuracy of CNC milling machines. This article presents a new methodology to identify systematic errors introduced due to the elastic deformations in the structure of CNC milling machines.

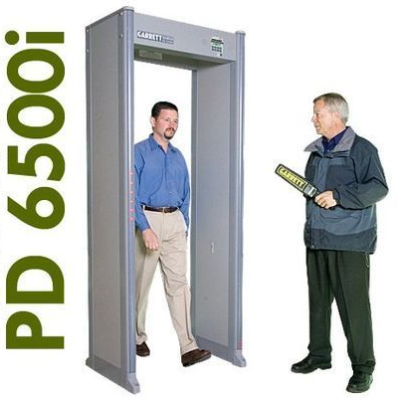

Door Frame Metal Detector - DFMD

Door Frame Metal Detector - DFMD Deep Search Metal Detector Repair - DSMD

Deep Search Metal Detector Repair - DSMD Non Linear Junction Detector - LNJD

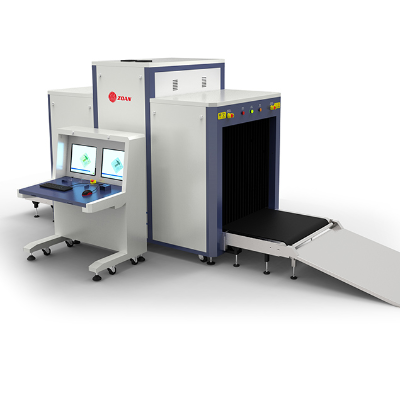

Non Linear Junction Detector - LNJD Baggage Scanner Machine Repair

Baggage Scanner Machine Repair Hand Held Metal Detector Repair

Hand Held Metal Detector Repair Lift Repair Service

Lift Repair Service Escalator Machine Repair

Escalator Machine Repair Fire Alarm Control Panel Repair

Fire Alarm Control Panel Repair Led Wall Panel Repair

Led Wall Panel Repair Home Theater Repair

Home Theater Repair Boom Barrier Repair

Boom Barrier Repair